Here's what Schiedel have to say about the Prima Plus and Prima Plus 1mm stainless steel single wall (single skin) wall flue system:

Installation

Mandatory Requirements

"Connection to an appliance which is not connected to the fuel supply, may be carried out by a competent person. However, connection to an appliance that is connected to the fuel supply must be carried out by a Gas Safe Engineer or OFTEC (oil) registered installer.

The flue system must be installed to comply with Building Regulations Document J (in England, Wales & Northern Ireland) Regulations for Scotland. The installation must also comply with BS7566 pts 1,2,3,4 for oil flues and BS5440 pt 1: 2000 for gas flues up to70kW".

Jointing

"The components are joined simply by pushing the engineered tolerance male spigot and female socket together until the stop is reached. No sealant is required. Use of a locking band is optional if greater joint security is felt to be required. The female socket should be installed uppermost to ensure any condensate drains smoothly down inside the flue. Terminals should be secured by a locking band or self-tapping screws.

Any flue pipe (i.e. single wall) connection to the chimney must be made in the same room as the appliance. The chimney must project at least 150mm below the ceiling.

Condensing gaskets should be fitted dry and lubricant applied to the female socket".

Adjustable Length

"Exact length can be obtained by use of the adjustable pipe andalso the 0-90 degree extendable adjustable bend. Adjustable pipes are not loadbearing therefore adequate support for the system must be provided immediately above".

Adjustable Bend

"Adjustable 0-90 degree bends enable rapid installation and alignment of the flue between appliance and chimney".

Connection to Appliance

"Always use an appliance connector, sealed using fire rope and fire cement or high temperature sealant. Connection to a condensing appliance the correct sealant must be used".

Appliance Removal

"Use of an adjustable length immediately above the appliance enables removal of the appliance later without dismantling the full system".

Painting

"If required to be painted, simply clean the surface with a solvent cleaner (White Spirit), apply a coat of primer and a top coat of high temperature paint that can withstand 550 degrees C. Extreme care must be taken when cleaning with solvent to ensure that it does not come into contact with the gasket if fitted".

Recommended distance to Combustibles

"As a single wall flue system the surface may get very hot and great care should be excerised to avoid touching any exposed section In accordance with the building regulations (Document J) the outer surface of the flue must be kept from any combustible material the distance as designated in the CE approval".

Support Components

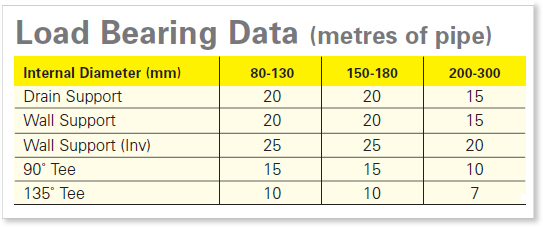

"The weight of a chimney system is considerable and requires independent support. No weight should be taken by the appliance. Refer to load bearing table below for full details of maximum loadings".

Wall brackets and roof brackets are not load bearing and mainly provide lateral support. Wall brackets should be fitted every 3m and at any offset. In domestic situations, a wall bracket or wall support MUST be used to support a tee when connected to a rear outlet appliance.

Horizontal runs should be supported every 1.5m. This can be increased to 4m with use of the extended locking band. Where the flue is free standing above the roof and its height exceeds 1.5m beyond the last support or the roof, a guy wire bracket must be used, and every 1.5m thereafter. Alternatively, a height of up to 3m can be achieved unsupported with the use of an extended locking band at the joint immediately below the last support and every joint above the roof level".

Installation of Prima Plus or a Prima Plus 1mm as a Liner

"The liner is lowered into the masonry stack a section at a time using either a lowering pipe or drain support to take the load. It is recommended that pipes are secured to each other using a locking band, or alternatively in non-condensing applications with self-tapping screws or rivets. The liner requires support at the base of the stack using a wall support, gather unit or drain support. Access to the base of the stack may well be required to fix the support as well as components such as tees and drain caps. Access will also be required to fix any bends necessary in the system. Intermediate support is required if the chimney length exceeds that given in the load-bearing data table. If insulation is required, normally granules such as Vermiculite should be poured in at this stage after fitting a suitable debris plate at the bottom of the system. Alternatively a solid tube of insulation can be used. To weather the top of the chimney stack and seal any gaps between the liner and the chimney pot appropriate acid-resistant mortar should be used".

After Installation

Testing before use

"This is done by means of flue flow test as described in BS5440:Part 1-2000. It can be summarised as follows:- After a visual and physical check of the joints in the system, and ensuring an adequate air supply for combustion has been provided, close all doors and windows in the room in which the appliance is to be installed. It will be necessary to introduce heat to the flue system for a minimum of 10 mins. and possibly up to 30 mins. using a blow torch or similar. Position a smoke pellet (providing a performance of 5m3 of smoke in 30 secs. burn time) at the intended of the appliance. The test is satisfactory if there is no significant spillage from the appliance position, no seepage over the length of the system, and discharge only from the terminal. If these conditions are not met, the test has failed and all faults must be rectified and the system retested before connection of the appliance to the fuel supply. In the event of any further problems, reference to BS5440:Part 1-2000 must be made".

Life Expectancy

"Under normal operating conditions and providing the system is installed correctly, it should last the lifetime of the appliance which is normally 10 to 12 years. Prima Plus carries a 10 year conditional warranty. The conditions are that the chimney is: correctly sized and installed; properly maintained/cleaned; burning only approved fuels in accordance with the Schiedel Rite-Vent and appliance manufacturer's instructions.

For recommended fuels listings, please refer to the HETAS guide, or by contacting the Solid Fuel Association (Tel: 0845 601 4406) or appliance manufacturer's instructions. Warranty registration details are provided with installation instructions for completion and registration with Schiedel Rite-Vent".

Maintenance

"It is essential that the flue way be kept clear at all times in the interest of good practise and health, safety and appliance performance. The system should be checked regularly during the appliance maintenance. (Refer appliance manufacturer's instructions)".

Return to previous page